Frequently Asked Questions.

We support all major CAD formats:

STEP, IGES, STL, SLDPRT, X_T, PARASOLID (and more).

Our engineers will review your design for manufacturability (DFM) and provide optimization suggestions before production begins.

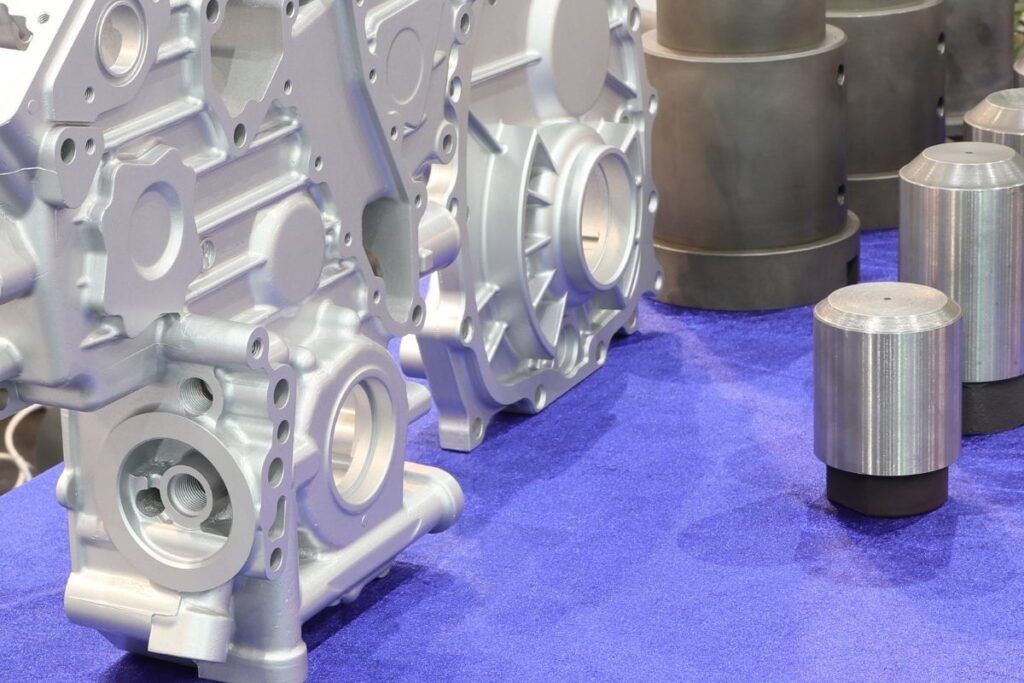

We offer a wide range of materials for various manufacturing processes, including:

- Metals (Aluminum, Steel, Titanium, etc.)

- Plastics (ABS, Nylon, Polycarbonate, etc.)

- Composites and specialized materials depending on the application. We also provide material consultation to help you select the most suitable materials for your project.

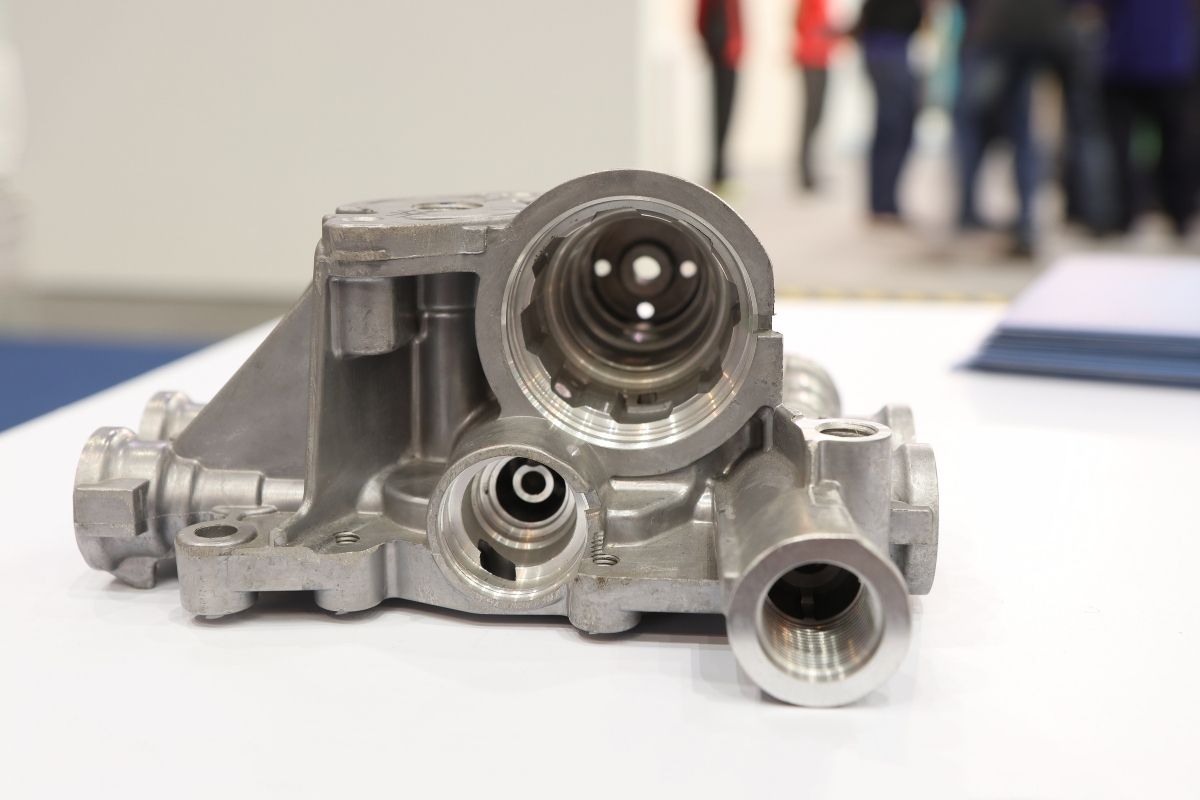

Absolutely. Our 5-axis CNC machining centers (±0.01mm) and industrial 3D printers excel at:

Intricate designs, thin walls, and internal features

Tolerances down to ±0.025mm for critical dimensions

Challenging materials (e.g., Inconel, PEEK, tool steels)

Absolutely! We offer a wide range of surface finishes and post-processing options to enhance both the appearance and functionality of your parts. Whether you need polishing, anodizing, painting, or another specific finish, we can accommodate your requirements.

Lead times vary depending on the service and project complexity. Rapid prototyping can typically be completed within a few days, while more complex manufacturing projects such as Low-volume production or tooling may take longer. Once we receive your project specifications, we’ll provide a detailed timeline.